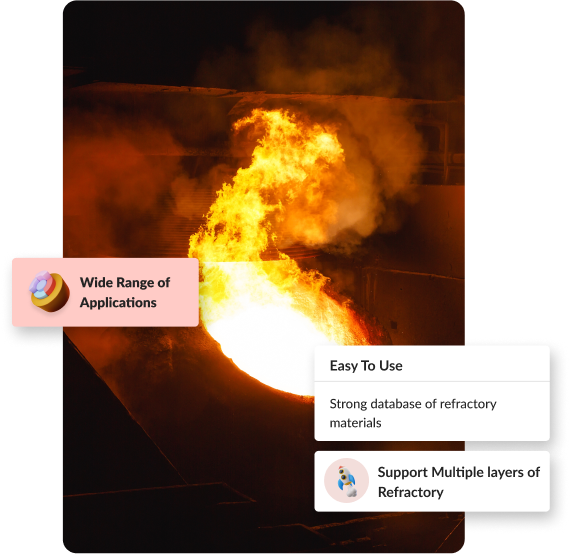

RefractoryThermal Simulation offers a lot of useful features for the high temperature

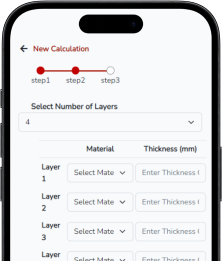

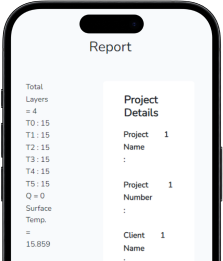

• Convenient handling of multi-calculation projects.

• Optimize refractory thickness, material selection, and operating conditions to minimize heat loss and maximize energy savings.

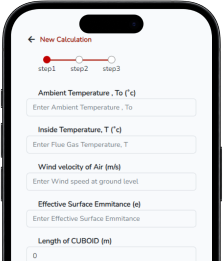

• Easy changing of materials, diameter, ambient and operation conditions for calculations of a project in one step

• Precise temperature calculations for each refractory layer interface

• Simple interface for users